High Performance

- 3 pre-validated sterilization cycles

- Sterilization of heat and moisture sensitive medical devices

- Detailed documented sterilization efficiency and material compatibility studies

Low Running Costs

- Complete solution and service provider

- Validated consumables

- H₂O, sterilization agent for 1 cycle

- Time and cycle cost saving

Advanced Technology

- Sterilization efficiency by advanced vaporizer system

- Improved RF Plasma technology

- User and Sterilant traceability

- USB and LAN connectivity

Environment User Friendly

- No toxic or hazardous residue

- Hydrogen peroxide composed to water and oxygen during sterilization

- Plug & Start feature

- No need for complicated water supply or air ventilation installation

Use Ergonomics

- Understandable and easy to use user interface

- Real time cycle monitoring and recording

- Validatable sterilization process

- Mobile and flexible

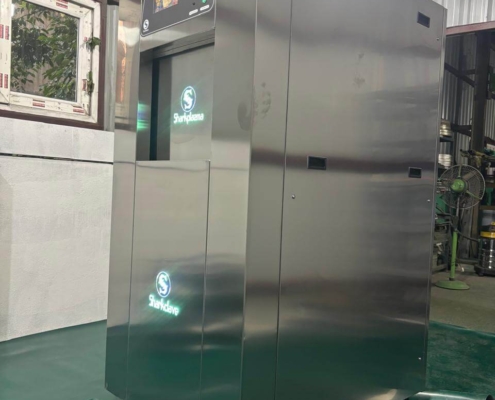

- Advanced sliding door

Service 24/7

- Service support and Software update through specifically online

- 24/7 all time